With 10 years experience working at Cullifords and seeing hundreds (if not thousands) of customers choosing their new work surface. There are certain questions or statements we hear from customers time and time again when making a decision. Probably the most common is “we can’t have marble in our kitchen can we?” or “we have been told by our designer/kitchen company that we can’t have marble”.

Having read a few articles and done various tests on untreated natural materials, there was little argument from myself on the matter. I would then move on to the huge number of Hard Quartzite, Granite, Ultra-compact or Engineered Quartz options available to see in our yard.

Alongside this reluctance to consider marble, we have many customers adamant on choosing it for their own kitchen. So this begs the question “What is it really like living with a marble work surface?”

Selection

To answer this question with any degree of accuracy, it’s beneficial to have personal experience of using a marble surface. So, when myself and my family were fortunate enough to have a new kitchen going in, I thought it was a great opportunity to live with a marble work surface and see for myself how it performs. By having it myself, I could see if it should be so easily dismissed. Please note my wife was fully on board with this experiment!

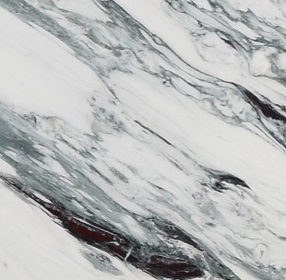

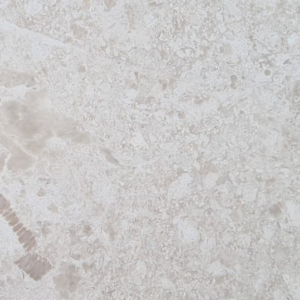

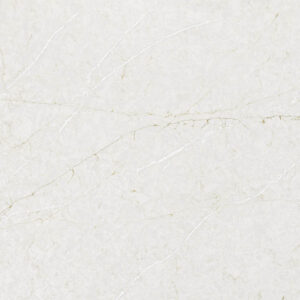

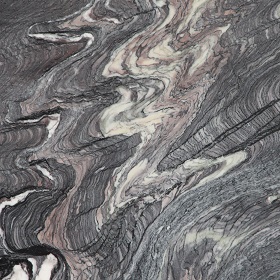

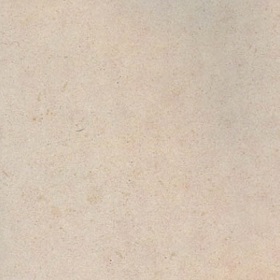

Having a North facing garden, we wanted a light surface but not overly busy. This led us to the Cullifords staple, Carrara marble. Carrara is one of the most popular and readily available white marbles and therefore relatively sustainable. Particularly when comparing to Quartz from the far east for example. This was definitely a factor in our decision making. Having a look at the numerous blocks of Cararra Cullifords had in stock, we settled for a Block 6264.

With the knowledge I did have of Carrara and most marbles being used in a kitchen setting, we decided on a honed finish. The main reason being, it helps disguise the potential etch marks that can occur when acidic substances make contact with the surface. With a polished finish, these marks would be more noticeable on areas of reflected light (see images further down in the blog).

Sealing

After installation, it’s advisable to allow the material to dry out for a few days prior to sealing. A surface can appear to be dry to the touch but the use of a moisture detector is useful for clarity. Luckily in our case, we had plenty of time after worktop installation and moving back in. This meant it was guaranteed to be very dry before it got its first use.

In most cases, the fabricator will seal your work surface after installation. They will determine how much sealer should be used dependent on the material. When looking at sealers, I was keen to use what we believe are the best sealers available and I opted for Dry Treat Dense Stone Impregnating Sealer. After checking the coverage for the type of material (Honed marble/10m2 per litre) I was having, I was ready to seal.

If you are not confident on carrying this process out yourself, then the stone fabricator will be happy to do it. In this instance, I was keen to understand a little more about the process, so undertook the job myself. Detailed instructions are available on the Dry Treat website as well as various Youtube videos that can help you do the job properly.

After sealing, the surface mustn’t be used for at least 24 hours and then will fully cure completely a few weeks afterwards. When sealing, the material initially went quite a lot darker. To my great relief the stone was back to its normal colour the next day.

Practical Use

Having seen marble taking in water (in the form of raindrops) at our yard on countless occasions, I was astonished at how well the sealer performed in repelling water. Any spillage beaded up on the surface as pictured above (links to videos). So the good news is that the sealer repels water, but what about dreaded stains like tea, coffee, soy sauce etc?

After 6 weeks of living and regular cooking, I am yet to report a permanent stain of any kind! I should note that we are adventurous cooks using a multitude of spices and sauces regularly.

On one occasion while we were baking cakes with the kids, an attachment for the mixer was left on the surface. The attachment must have had butter or oil on it, and was subsequently left on the top for a prolonged period. This resulted in an oily mark in the stone which I unfortunately didn’t get a photo of. In this instance I made a poultice from Dry Treat Oxy_Klenza. This was a very straight forward process and to my amazement, the oil mark disappeared after 24hours.

Etching

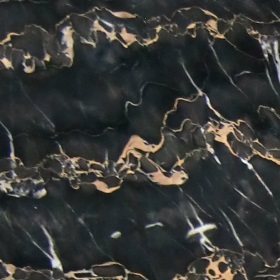

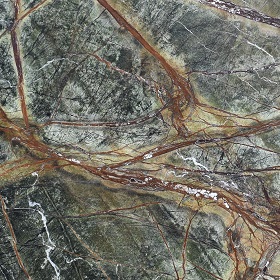

So now you might be thinking, “Great! there’s no reason not to get a marble work surface”. Well, despite the amazing results from my impregnating sealer, there are downsides to having marble. One issue we have experienced a few times is acid etching.

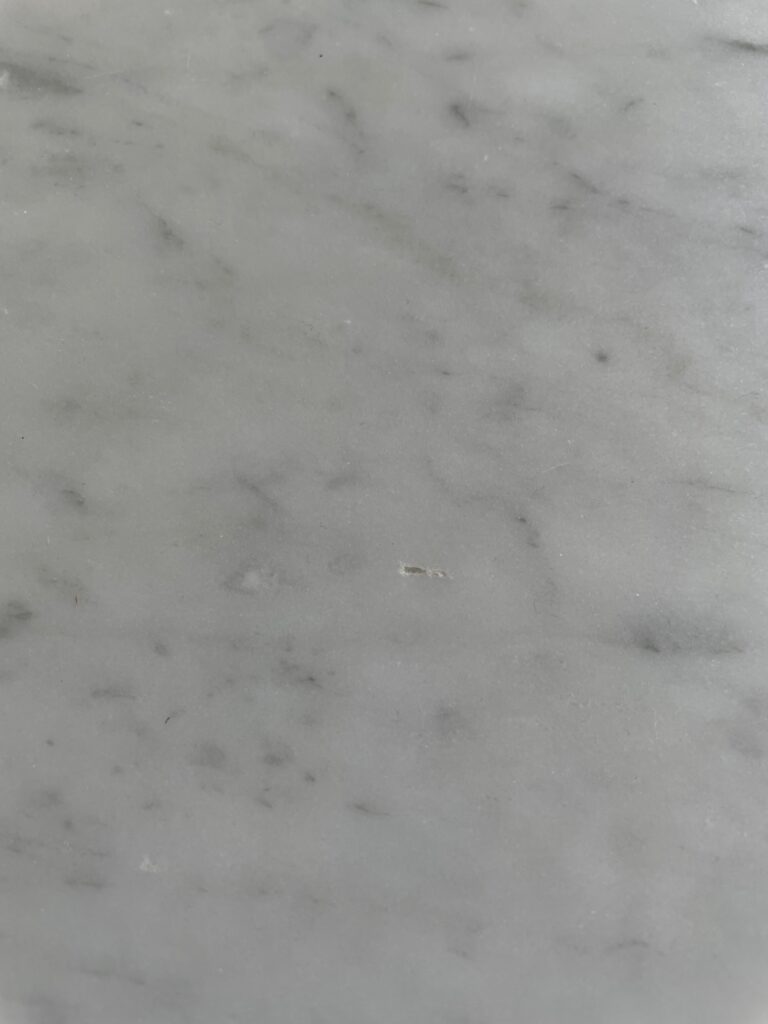

Due to the high percentage of calcium (or calcite) in most marbles, it can be susceptible to etching from acidic substances. Although the sealer does a great job of repelling substances, contact is still made on the surface. This can lead to the acidic liquid (fruit juice, vinegar etc) eating the calcium in the stone and leaving a patchy mark as shown below. The mark shown in the image is around 3 weeks old and is less noticeable than when it first occurred. Also, as stated earlier in the blog, the kitchen faces North and therefore not a huge amount of light flows in. This undoubtedly makes the marks more difficult to see.

There are a few of these in the kitchen but to notice them, you would need to bend down to a certain level and catch it in the light from the window. As shown in the image below on the right, it is unnoticeable from different angles.

Scratching

Another potential sticking point would be that generally speaking, marble is softer and susceptible to scratching. At Cullifords, we put marble into three categories: Hard marble, normal marble and decorative marble. Carrara would fit into the normal category. The harder types will be less easy to scratch and decorative more so. Where we had kept a ceramic utensil holder and it being moved, this has lead to a couple of scratches. However, as you can see in the image on the right, they are a little less noticeable in reality.

The benefit of marble however is that the surface can be polished/honed in situ. There are companies who can come out and bring it back to it’s former glory if you want. This cannot be done with a quartz or porcelain surface in the same manner. In our case, we are quite happy to live with the odd mark/scratch as it stands.

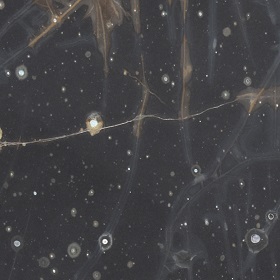

Taroli

Taroli is a term used in the stone industry for a natural occurrence in marble and most prominently in Carrara. They are small sand holes or pits in the surface of the stone. All stone blocks that are quarried are treated by introducing a clear or colour matched resin. This will fill any imperfections that are inevitable with natural stone to create a smooth surface. Some of these pits are so small that resin cannot take hold and therefore a small hole is present. This is completely normal and does not mean that your slab of marble is defective in any way.

Some blocks have more Taroli than others and at Cullifords, we lay out our slabs on special racking systems. This allows you to view the entire slab carefully and make a much more informed decision.

Conclusion

So, can you have marble in your kitchen? The answer is yes, of course! The information in this blog is intended to inform you fully of the realities of living with a marble work surface. When I walk into the kitchen, I know 100% that i made the right decision in going for marble. I also fully understand that for some people it may drive them crazy.

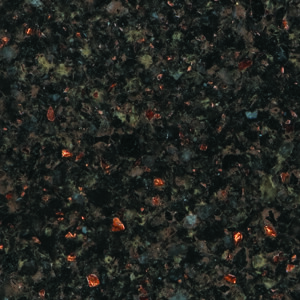

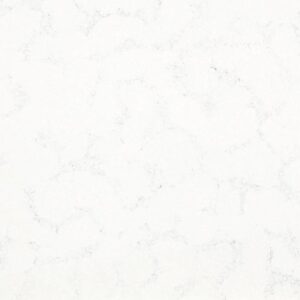

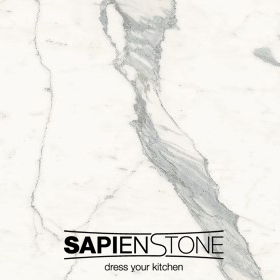

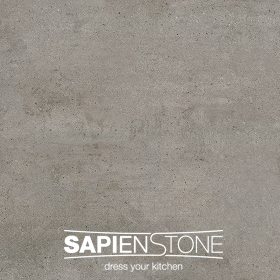

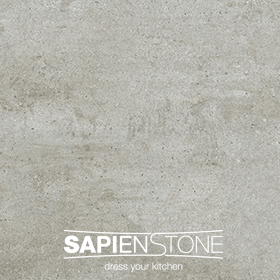

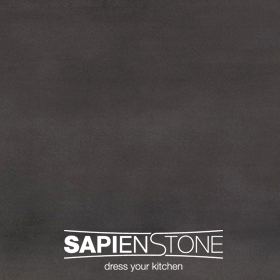

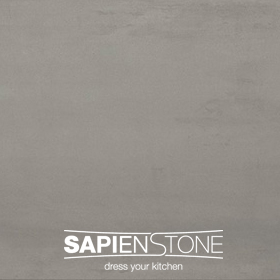

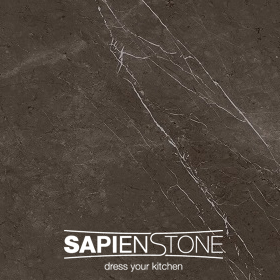

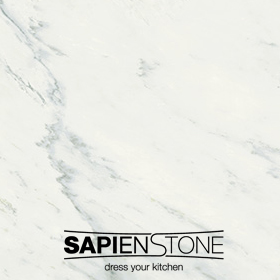

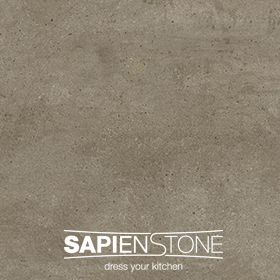

If you are the type to worry about marks in the stone or be panicked every time someone puts a cup down, then perhaps this isn’t the material for you. The good news for you however, is that we offer plenty of products that are more maintenance friendly in our current stock. Products such as quartz from Radianz, Cullifords quartz or ultra compact surfaces from Sapienstone. There are also a plethora of granite or quartzite options that you can see at our yard in full.

At Cullifords, we inspire the customer to make informed choices about stone. So, if you have an upcoming project requiring stone slab or tile, contact Cullifords . Our yard is open and waiting for you to find your perfect material.

This blog was written by Matthew Leary, Business Development Manager at Cullifords. For any questions regarding the use of marble in a kitchen environment, feel free to email matthew@geraldculliford.co.uk

African Red

African Red  Alba Chiara

Alba Chiara  Alicante

Alicante  Alma Grey

Alma Grey  Amazonite

Amazonite  Andromeda White

Andromeda White  Angola Black

Angola Black  Angola Silver

Angola Silver  Antique Gold

Antique Gold  Aqua Marina

Aqua Marina  Arabescato Cervaiole

Arabescato Cervaiole  Arabescato Corchia

Arabescato Corchia  Arabescato Orobico Grigio

Arabescato Orobico Grigio  Arabescato Orobico Rosso

Arabescato Orobico Rosso  Arabescato Portugal

Arabescato Portugal  Arabescato Vagli

Arabescato Vagli  Aran White

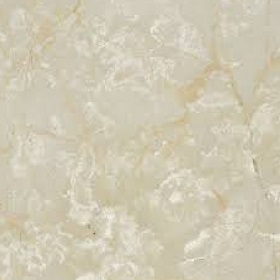

Aran White  Arctic Cream

Arctic Cream  Astoria

Astoria  Atlantic Stone

Atlantic Stone  Aurisina Fiorito

Aurisina Fiorito  Avalanche

Avalanche  Azul Aran

Azul Aran  Azul Bahia

Azul Bahia  Azul Boquira

Azul Boquira  Azul Extremadura

Azul Extremadura  Azul Imperial

Azul Imperial  Azul Louro

Azul Louro  Azul Macaubas

Azul Macaubas  Azul Platino

Azul Platino  Baltic Brown

Baltic Brown  Baltic Green

Baltic Green  Basaltina

Basaltina Bateig Beige

Bateig Beige  Bateig Blue

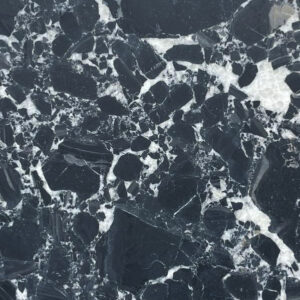

Bateig Blue  Belgian Black

Belgian Black  Belgian Fossil

Belgian Fossil  Belize

Belize  Belvedere

Belvedere  Bethel White

Bethel White  Bianco Covelano

Bianco Covelano  Bianco Iberico

Bianco Iberico  Bianco Ibiza

Bianco Ibiza  Bianco Lasa Marble

Bianco Lasa Marble Bianco Macaubas

Bianco Macaubas  Bianco V

Bianco V Black Forest

Black Forest  Black Horse

Black Horse  Black Ice

Black Ice Black Silk

Black Silk  Black Tempest

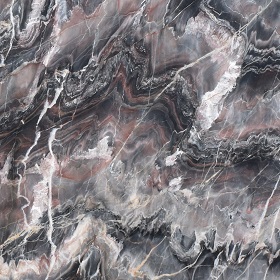

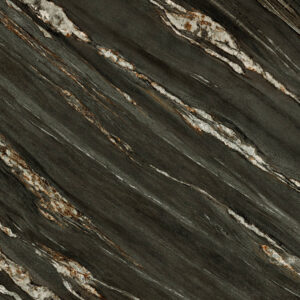

Black Tempest  Blackwood

Blackwood  Bleu de Sovoie

Bleu de Sovoie  Blue De Savoie

Blue De Savoie  Blue Eyes

Blue Eyes  Bon Accord

Bon Accord  Botticino Classico

Botticino Classico  Botticino Fiorito

Botticino Fiorito  Breccia Capraia

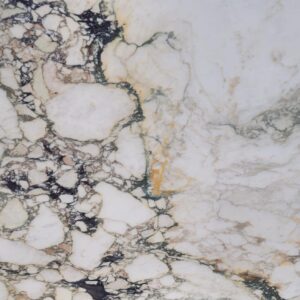

Breccia Capraia  Breccia Fantastico

Breccia Fantastico  Breccia Medicea

Breccia Medicea  Breccia Supreme

Breccia Supreme  Brown Silk

Brown Silk  Calacatta

Calacatta Calacatta Apuano

Calacatta Apuano  Calacatta Imperial

Calacatta Imperial  Calacatta Michaelangelo

Calacatta Michaelangelo  Calacatta Oro

Calacatta Oro  Calacatta Portugal

Calacatta Portugal  Calacatta Rosata

Calacatta Rosata  Calacatta Vagli

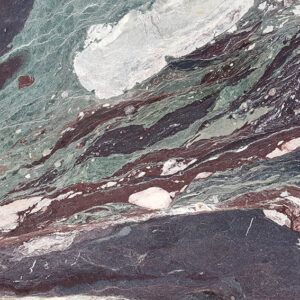

Calacatta Vagli  Calacatta Verde

Calacatta Verde  Calacatta Viola

Calacatta Viola  Calacatta Viola Estramoz

Calacatta Viola Estramoz  Calacatta Viola Fantastico

Calacatta Viola Fantastico  Calcite Blue

Calcite Blue Campobello

Campobello  Capolavoro

Capolavoro  Caravaggio Marble

Caravaggio Marble  Caravaggio Quartzite

Caravaggio Quartzite  Carib Gold

Carib Gold  Carrara

Carrara  Colonial Gold

Colonial Gold  Colonial White

Colonial White  Confusion

Confusion Copenhagen

Copenhagen  Cosmic Black

Cosmic Black  Costa Smeralda

Costa Smeralda  Crema Evora

Crema Evora  Crema Evora Venato

Crema Evora Venato  Crema Marfil

Crema Marfil  Cristallo

Cristallo  Crystal Blue

Crystal Blue  Cullifords Ceramic – Agata Atena

Cullifords Ceramic – Agata Atena  Cullifords Ceramic – Agata Black

Cullifords Ceramic – Agata Black  Cullifords Ceramic – Agata Blu

Cullifords Ceramic – Agata Blu  Cullifords Ceramic – Amazonite

Cullifords Ceramic – Amazonite  Cullifords Ceramic – Arabescato Orobico

Cullifords Ceramic – Arabescato Orobico  Cullifords Ceramic – Arabescato Statuario

Cullifords Ceramic – Arabescato Statuario  Cullifords Ceramic – Azul Bateig Limestone

Cullifords Ceramic – Azul Bateig Limestone  Cullifords Ceramic – Azul Macaubas

Cullifords Ceramic – Azul Macaubas  Cullifords Ceramic – Bardiglio Chiaro

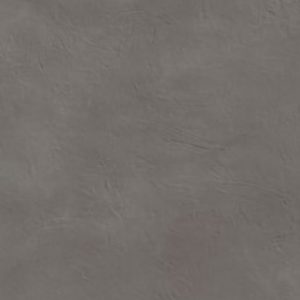

Cullifords Ceramic – Bardiglio Chiaro  Cullifords Ceramic – Basaltina Antracite

Cullifords Ceramic – Basaltina Antracite  Cullifords Ceramic – Basaltina Grey

Cullifords Ceramic – Basaltina Grey  Cullifords Ceramic – Basaltina Moka

Cullifords Ceramic – Basaltina Moka  Cullifords Ceramic – Basaltina Sand

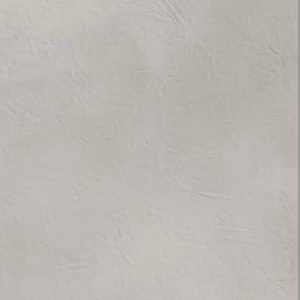

Cullifords Ceramic – Basaltina Sand  Cullifords Ceramic – Basaltina White

Cullifords Ceramic – Basaltina White  Cullifords Ceramic – Bianco

Cullifords Ceramic – Bianco  Cullifords Ceramic – Bianco Calacatta

Cullifords Ceramic – Bianco Calacatta  Cullifords Ceramic – Bianco Carrara

Cullifords Ceramic – Bianco Carrara  Cullifords Ceramic – Bianco Covelano

Cullifords Ceramic – Bianco Covelano  Cullifords Ceramic – Bianco Statuario

Cullifords Ceramic – Bianco Statuario  Cullifords Ceramic – Black Plate

Cullifords Ceramic – Black Plate  Cullifords Ceramic – Blue Zinc

Cullifords Ceramic – Blue Zinc  Cullifords Ceramic – Brilliant Green

Cullifords Ceramic – Brilliant Green  Cullifords Ceramic – Brown Quartz

Cullifords Ceramic – Brown Quartz  Cullifords Ceramic – Brown Zinc

Cullifords Ceramic – Brown Zinc  Cullifords Ceramic – Calacatta

Cullifords Ceramic – Calacatta  Cullifords Ceramic – Calacatta Bellissimo

Cullifords Ceramic – Calacatta Bellissimo  Cullifords Ceramic – Calacatta Dorato

Cullifords Ceramic – Calacatta Dorato Cullifords Ceramic – Calacatta Elite

Cullifords Ceramic – Calacatta Elite Cullifords Ceramic – Calacatta Light

Cullifords Ceramic – Calacatta Light  Cullifords Ceramic – Calacatta Lincoln

Cullifords Ceramic – Calacatta Lincoln  Cullifords Ceramic – Calacatta Macchia Vecchia

Cullifords Ceramic – Calacatta Macchia Vecchia  Cullifords Ceramic – Calacatta Supremo

Cullifords Ceramic – Calacatta Supremo Cullifords Ceramic – Calacatta Viola

Cullifords Ceramic – Calacatta Viola  Cullifords Ceramic – Calce

Cullifords Ceramic – Calce  Cullifords Ceramic – Capraia

Cullifords Ceramic – Capraia  Cullifords Ceramic – Cardosa

Cullifords Ceramic – Cardosa  Cullifords Ceramic – Cloud

Cullifords Ceramic – Cloud  Cullifords Ceramic – Crema Delicato

Cullifords Ceramic – Crema Delicato  Cullifords Ceramic – Crema Luna

Cullifords Ceramic – Crema Luna  Cullifords Ceramic – Crema Marfil

Cullifords Ceramic – Crema Marfil  Cullifords Ceramic – Crystal Dark

Cullifords Ceramic – Crystal Dark  Cullifords Ceramic – Crystal Grey

Cullifords Ceramic – Crystal Grey  Cullifords Ceramic – Crystal Sky

Cullifords Ceramic – Crystal Sky  Cullifords Ceramic – Daino Grigio

Cullifords Ceramic – Daino Grigio  Cullifords Ceramic – Dark Emperador

Cullifords Ceramic – Dark Emperador  Cullifords Ceramic – Dove Grey

Cullifords Ceramic – Dove Grey  Cullifords Ceramic – Earth

Cullifords Ceramic – Earth  Cullifords Ceramic – Ebano

Cullifords Ceramic – Ebano  Cullifords Ceramic – Estremoz

Cullifords Ceramic – Estremoz  Cullifords Ceramic – Fior Di Bosco

Cullifords Ceramic – Fior Di Bosco  Cullifords Ceramic – Gem Pearl

Cullifords Ceramic – Gem Pearl  Cullifords Ceramic – Gem Rose

Cullifords Ceramic – Gem Rose  Cullifords Ceramic – Gem Violet

Cullifords Ceramic – Gem Violet  Cullifords Ceramic – Gold Onyx

Cullifords Ceramic – Gold Onyx  Cullifords Ceramic – Graphite

Cullifords Ceramic – Graphite  Cullifords Ceramic – Green Onyx Vein Cut

Cullifords Ceramic – Green Onyx Vein Cut  Cullifords Ceramic – Grey Beauty

Cullifords Ceramic – Grey Beauty  Cullifords Ceramic – Grey Marble

Cullifords Ceramic – Grey Marble  Cullifords Ceramic – Grey Onyx Vein Cut

Cullifords Ceramic – Grey Onyx Vein Cut  Cullifords Ceramic – Grey Plate

Cullifords Ceramic – Grey Plate  Cullifords Ceramic – Grey Quartz

Cullifords Ceramic – Grey Quartz  Cullifords Ceramic – Grey Zinc

Cullifords Ceramic – Grey Zinc  Cullifords Ceramic – Grigio Carnico

Cullifords Ceramic – Grigio Carnico  Cullifords Ceramic – Gris De Savoie

Cullifords Ceramic – Gris De Savoie  Cullifords Ceramic – Imperial Grey

Cullifords Ceramic – Imperial Grey  Cullifords Ceramic – Ink

Cullifords Ceramic – Ink  Cullifords Ceramic – Iron

Cullifords Ceramic – Iron  Cullifords Ceramic – Jerusalem Limestone

Cullifords Ceramic – Jerusalem Limestone  Cullifords Ceramic – Light Grey

Cullifords Ceramic – Light Grey  Cullifords Ceramic – Liquid Green

Cullifords Ceramic – Liquid Green  Cullifords Ceramic – Liquid Purple

Cullifords Ceramic – Liquid Purple  Cullifords Ceramic – Luce Black

Cullifords Ceramic – Luce Black  Cullifords Ceramic – Luce Blue

Cullifords Ceramic – Luce Blue  Cullifords Ceramic – Luce Gold

Cullifords Ceramic – Luce Gold  Cullifords Ceramic – Luce Grey

Cullifords Ceramic – Luce Grey  Cullifords Ceramic – Luce Pearl

Cullifords Ceramic – Luce Pearl  Cullifords Ceramic – Luce Silver

Cullifords Ceramic – Luce Silver  Cullifords Ceramic – Michelangelo Altissimo

Cullifords Ceramic – Michelangelo Altissimo  Cullifords Ceramic – Nero

Cullifords Ceramic – Nero  Cullifords Ceramic – Nero Marquina

Cullifords Ceramic – Nero Marquina  Cullifords Ceramic – Onice Ambra

Cullifords Ceramic – Onice Ambra  Cullifords Ceramic – Onice Bianco Extra

Cullifords Ceramic – Onice Bianco Extra  Cullifords Ceramic – Onice Ghiaccio

Cullifords Ceramic – Onice Ghiaccio  Cullifords Ceramic – Onice Grigio

Cullifords Ceramic – Onice Grigio  Cullifords Ceramic – Onice Ivory

Cullifords Ceramic – Onice Ivory  Cullifords Ceramic – Onice Malaga

Cullifords Ceramic – Onice Malaga  Cullifords Ceramic – Onice Miele

Cullifords Ceramic – Onice Miele  Cullifords Ceramic – Onice Nero

Cullifords Ceramic – Onice Nero  Cullifords Ceramic – Onice Persia

Cullifords Ceramic – Onice Persia  Cullifords Ceramic – Onice Pesca

Cullifords Ceramic – Onice Pesca  Cullifords Ceramic – Paonazzetto

Cullifords Ceramic – Paonazzetto  Cullifords Ceramic – Pietra Di Vals

Cullifords Ceramic – Pietra Di Vals  Cullifords Ceramic – Pietra Grey

Cullifords Ceramic – Pietra Grey  Cullifords Ceramic – Pietra Piasentina

Cullifords Ceramic – Pietra Piasentina  Cullifords Ceramic – Piombo

Cullifords Ceramic – Piombo  Cullifords Ceramic – Premium White

Cullifords Ceramic – Premium White  Cullifords Ceramic – Pulpis Bronze

Cullifords Ceramic – Pulpis Bronze  Cullifords Ceramic – Rosso Imperiale

Cullifords Ceramic – Rosso Imperiale  Cullifords Ceramic – Sahara Noir

Cullifords Ceramic – Sahara Noir  Cullifords Ceramic – San Vicente Limestone

Cullifords Ceramic – San Vicente Limestone  Cullifords Ceramic – Silicio

Cullifords Ceramic – Silicio  Cullifords Ceramic – Silver

Cullifords Ceramic – Silver  Cullifords Ceramic – Smoke

Cullifords Ceramic – Smoke  Cullifords Ceramic – Sodalite Blue

Cullifords Ceramic – Sodalite Blue  Cullifords Ceramic – Statuario Altissimo

Cullifords Ceramic – Statuario Altissimo  Cullifords Ceramic – Statuario Ultra

Cullifords Ceramic – Statuario Ultra Cullifords Ceramic – Talc

Cullifords Ceramic – Talc  Cullifords Ceramic – Taupe

Cullifords Ceramic – Taupe  Cullifords Ceramic – Thassos

Cullifords Ceramic – Thassos  Cullifords Ceramic – Tobacco

Cullifords Ceramic – Tobacco  Cullifords Ceramic – Travertino Navona

Cullifords Ceramic – Travertino Navona  Cullifords Ceramic – Travertino Santa Caterina

Cullifords Ceramic – Travertino Santa Caterina  Cullifords Ceramic – Tropical Black

Cullifords Ceramic – Tropical Black  Cullifords Ceramic – Tundra Grey

Cullifords Ceramic – Tundra Grey  Cullifords Ceramic – Venice Ivory

Cullifords Ceramic – Venice Ivory  Cullifords Ceramic – Venice Zinc

Cullifords Ceramic – Venice Zinc  Cullifords Ceramic – Verde Karzai

Cullifords Ceramic – Verde Karzai  Cullifords Ceramic – Verde St. Denis

Cullifords Ceramic – Verde St. Denis  Cullifords Ceramic – White Beauty

Cullifords Ceramic – White Beauty  Cullifords Ceramic – White Quartz

Cullifords Ceramic – White Quartz  Cullifords Quartz – Alpine Shimmer

Cullifords Quartz – Alpine Shimmer Cullifords Quartz – Bianco Eclipsia

Cullifords Quartz – Bianco Eclipsia Cullifords Quartz – Calacatta Amber

Cullifords Quartz – Calacatta Amber Cullifords Quartz – Calacatta Oro

Cullifords Quartz – Calacatta Oro Cullifords Quartz – Calacatta Vagli Oro (Book-Matched)

Cullifords Quartz – Calacatta Vagli Oro (Book-Matched) Cullifords Quartz – Carrara

Cullifords Quartz – Carrara Cullifords Quartz – Carrara Zero (less than 1% Silica)

Cullifords Quartz – Carrara Zero (less than 1% Silica) Cullifords Quartz – Enigma

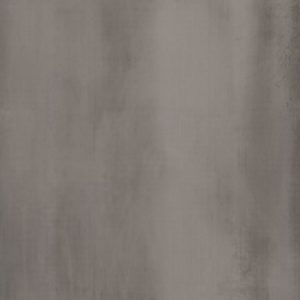

Cullifords Quartz – Enigma Cullifords Quartz – Grey Concrete

Cullifords Quartz – Grey Concrete Cullifords Quartz – Grey Mirror

Cullifords Quartz – Grey Mirror Cullifords Quartz – Grey Shimmer

Cullifords Quartz – Grey Shimmer Cullifords Quartz – Medicea (Book-Matched)

Cullifords Quartz – Medicea (Book-Matched) Cullifords Quartz – Misty Carrara Satinato

Cullifords Quartz – Misty Carrara Satinato Cullifords Quartz – Polido

Cullifords Quartz – Polido Cullifords Quartz – White Mirror

Cullifords Quartz – White Mirror Daino Reale

Daino Reale  Dakota Mahogany

Dakota Mahogany  Diamond Fall

Diamond Fall  Dolce Vita

Dolce Vita  Dolomite White

Dolomite White  Dove Nuvolato

Dove Nuvolato  Dover White

Dover White  Duke Black

Duke Black  Duke White

Duke White  Ebony

Ebony  Elegante Grey

Elegante Grey  Emerald Glitter

Emerald Glitter  Emperador

Emperador  Eramosa Crosscut

Eramosa Crosscut Eramosa Vein Cut

Eramosa Vein Cut  Estramoz

Estramoz  Fior Di Bosco

Fior Di Bosco  Fior Di Pesco Carnico

Fior Di Pesco Carnico  Four Seasons

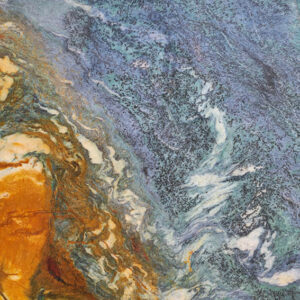

Four Seasons  Fusion Blue

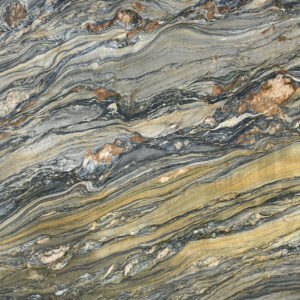

Fusion Blue  Fusion Explosion

Fusion Explosion Fusion Fire

Fusion Fire  Fusion Green

Fusion Green Fusion Wow Multicolour

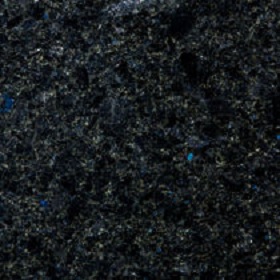

Fusion Wow Multicolour  Galaxy

Galaxy  Ghibli

Ghibli  Gold Macaubus

Gold Macaubus  Golden Eclipse

Golden Eclipse  Golden Spice

Golden Spice  Gran Perla

Gran Perla  Grand Antique

Grand Antique Grand Constantine

Grand Constantine Green Galaxy

Green Galaxy  Grey Marquina

Grey Marquina  Grigio Billiemi

Grigio Billiemi  Grigio Carnico

Grigio Carnico  Gris Pulpis

Gris Pulpis  Gris Versilia

Gris Versilia  Himalayan White

Himalayan White  Iron Red

Iron Red  Ivory Fantasy

Ivory Fantasy  Ivory Onyx

Ivory Onyx  Jade

Jade  Jade River

Jade River Jordan Pink

Jordan Pink  Juparana Bordeaux

Juparana Bordeaux  Juparana Indiano

Juparana Indiano  Juparana Rio

Juparana Rio  Jura Beige

Jura Beige  Jura Blue Grey

Jura Blue Grey  Jurassic Green

Jurassic Green Kashmir Gold

Kashmir Gold  Kashmir White

Kashmir White  Katuba Blue

Katuba Blue Kuru Grey

Kuru Grey  Labrador Black

Labrador Black  Labradorite Bianca

Labradorite Bianca  Lady Dream

Lady Dream  Lagoa Pink

Lagoa Pink  Laguna Blue

Laguna Blue  Lemon Spice

Lemon Spice  Lemurian Blue

Lemurian Blue  Lilac

Lilac  London White

London White  Louise Blue

Louise Blue  Luana Multicolour

Luana Multicolour  Luna Pearl

Luna Pearl  LUNDHS Antique

LUNDHS Antique  LUNDHS Antique Silk

LUNDHS Antique Silk  LUNDHS Blue

LUNDHS Blue  LUNDHS Blue Silk

LUNDHS Blue Silk  LUNDHS Emerald

LUNDHS Emerald  LUNDHS Emerald Silk

LUNDHS Emerald Silk  LUNDHS Royal

LUNDHS Royal  LUNDHS Royal Silk

LUNDHS Royal Silk  Macaubas Sky

Macaubas Sky  Magma Black

Magma Black  Magma Gold

Magma Gold  Magnesite

Magnesite  Majestic Brown

Majestic Brown  Marinace Aquarius

Marinace Aquarius  Marinace Black and Gold

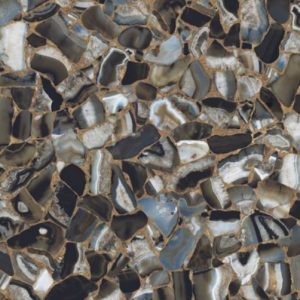

Marinace Black and Gold  Marinace Black and White

Marinace Black and White  Marinace Rosso

Marinace Rosso  Marinace Verde

Marinace Verde  Marron Coheiba

Marron Coheiba  Marron Imperial

Marron Imperial Matrix Satinato

Matrix Satinato  Maui

Maui  Meteorus

Meteorus  Midnight Blue

Midnight Blue  Millenium Cream

Millenium Cream  Moca Creme

Moca Creme  Moleanos

Moleanos  Moleanos Blue

Moleanos Blue  Moleanos Fine Grain

Moleanos Fine Grain  Moon Agate

Moon Agate  Moroccan Black Fossil

Moroccan Black Fossil  Moroccan Brown Fossil

Moroccan Brown Fossil  Mosaikus

Mosaikus  Nero Marquina

Nero Marquina Nero Portoro

Nero Portoro  Noir St. Laurent

Noir St. Laurent  Nordic Sunset

Nordic Sunset  Norwegian Rose

Norwegian Rose  Nuvola

Nuvola  Occhio di Pavone

Occhio di Pavone  Ocean Storm

Ocean Storm  Olive Green

Olive Green  Onyx Cappucino

Onyx Cappucino  Onyx Green

Onyx Green  Onyx Honey

Onyx Honey  Onyx Pink

Onyx Pink  Onyx Smeraldo

Onyx Smeraldo  Opera D’Arte

Opera D’Arte  Optimum Ceramics – Arabescato Corchia

Optimum Ceramics – Arabescato Corchia  Optimum Ceramics – Atlantic Grey

Optimum Ceramics – Atlantic Grey  Optimum Ceramics – Black Marquina

Optimum Ceramics – Black Marquina  Optimum Ceramics – Black Tempest

Optimum Ceramics – Black Tempest  Optimum Ceramics – Borghini

Optimum Ceramics – Borghini  Optimum Ceramics – Calacatta Gold

Optimum Ceramics – Calacatta Gold  Optimum Ceramics – Calacatta Matarazzo

Optimum Ceramics – Calacatta Matarazzo  Optimum Ceramics – Calacatta Supreme

Optimum Ceramics – Calacatta Supreme  Optimum Ceramics – Concrete Graphite

Optimum Ceramics – Concrete Graphite  Optimum Ceramics – Concrete Light Grey

Optimum Ceramics – Concrete Light Grey  Optimum Ceramics – Concrete White

Optimum Ceramics – Concrete White  Optimum Ceramics – Fior Di Bosco

Optimum Ceramics – Fior Di Bosco  Optimum Ceramics – Gold Laurent

Optimum Ceramics – Gold Laurent  Optimum Ceramics – Imperial Brown

Optimum Ceramics – Imperial Brown  Optimum Ceramics – Limestone Ivory

Optimum Ceramics – Limestone Ivory  Optimum Ceramics – Macchia Vecchia

Optimum Ceramics – Macchia Vecchia  Optimum Ceramics – Pietra Di Fez

Optimum Ceramics – Pietra Di Fez  Optimum Ceramics – Pietra Grey

Optimum Ceramics – Pietra Grey  Optimum Ceramics – Portland

Optimum Ceramics – Portland  Optimum Ceramics – Statuario

Optimum Ceramics – Statuario  Optimum Ceramics – Super White

Optimum Ceramics – Super White  Optimum Ceramics – Taj Mahal

Optimum Ceramics – Taj Mahal  Optimum Ceramics – Travertino Classico

Optimum Ceramics – Travertino Classico  Pakistan Black and Gold

Pakistan Black and Gold Palissandro Black

Palissandro Black  Palissandro Bluette

Palissandro Bluette  Palissandro Classico

Palissandro Classico  Palissandro Nuvolato

Palissandro Nuvolato  Panda White

Panda White  Panna Fragola

Panna Fragola  Paradiso Classico

Paradiso Classico  Patagonia

Patagonia  Pegasus

Pegasus  Perla Beige

Perla Beige  Pietra Del Cardosa

Pietra Del Cardosa  Pietra Lavica

Pietra Lavica  Pietra Piasentina

Pietra Piasentina  Pietra Serena

Pietra Serena  Piracema

Piracema  Platinum Macaubus

Platinum Macaubus  Radianz – Mystic Platinum

Radianz – Mystic Platinum  Radianz – Alluring

Radianz – Alluring  Radianz – Antique Brown

Radianz – Antique Brown  Radianz – Argento Gold

Radianz – Argento Gold  Radianz – Calacatta Alya

Radianz – Calacatta Alya  Radianz – Carola

Radianz – Carola  Radianz – Diamond White

Radianz – Diamond White  Radianz – Everest White

Radianz – Everest White  Radianz – Hercules

Radianz – Hercules  Radianz – Kunlun Ink

Radianz – Kunlun Ink  Radianz – Lucern Lake

Radianz – Lucern Lake  Radianz – Mare Blu

Radianz – Mare Blu  Radianz – Mariposa Buff

Radianz – Mariposa Buff  Radianz – Mirama Bronze

Radianz – Mirama Bronze  Radianz – Orion

Radianz – Orion  Radianz – Rio

Radianz – Rio  Radianz – Royal Marfil

Radianz – Royal Marfil  Radianz – Ural Grey

Radianz – Ural Grey  Radianz- Antique Green

Radianz- Antique Green  Rainforest Green

Rainforest Green  Roma Blue

Roma Blue  Rosa Tea

Rosa Tea  Rose Aurora

Rose Aurora  Rose Aurora Estramoz

Rose Aurora Estramoz  Rose Aurora Macchia Vecchia

Rose Aurora Macchia Vecchia  Rose Noir

Rose Noir  Rosso Bilbao

Rosso Bilbao  Rosso Damascus

Rosso Damascus  Rosso Dante

Rosso Dante  Rosso Levanto

Rosso Levanto  Rosso Luana

Rosso Luana  Rosso Verona

Rosso Verona  Royal Blue

Royal Blue  Ruivina

Ruivina Salome

Salome  San Simone

San Simone  Sapien Stone – Alaska White

Sapien Stone – Alaska White  Sapien Stone – Arabescato

Sapien Stone – Arabescato  Sapien Stone – Balance – Chester Green

Sapien Stone – Balance – Chester Green  Sapien Stone – Balance – Ivory

Sapien Stone – Balance – Ivory  Sapien Stone – Balance – Luna Limestone

Sapien Stone – Balance – Luna Limestone  Sapien Stone – Balance – Masala Red

Sapien Stone – Balance – Masala Red  Sapien Stone – Balance – Nude

Sapien Stone – Balance – Nude  Sapien Stone – Basalt Black

Sapien Stone – Basalt Black  Sapien Stone – Basalt Cream

Sapien Stone – Basalt Cream  Sapien Stone – Bianco Lasa

Sapien Stone – Bianco Lasa  Sapien Stone – Black Diamond

Sapien Stone – Black Diamond  Sapien Stone – Breccia Imperiale

Sapien Stone – Breccia Imperiale  Sapien Stone – Bright Onyx

Sapien Stone – Bright Onyx  Sapien Stone – Brown Earth

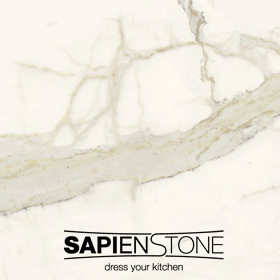

Sapien Stone – Brown Earth  Sapien Stone – Calacatta

Sapien Stone – Calacatta  Sapien Stone – Calacatta Light

Sapien Stone – Calacatta Light  Sapien Stone – Calacatta Macchia Vecchia

Sapien Stone – Calacatta Macchia Vecchia  Sapien Stone – Calacatta Statuario

Sapien Stone – Calacatta Statuario  Sapien Stone – Calacatta Viola

Sapien Stone – Calacatta Viola  Sapien Stone – Ceppo Varese

Sapien Stone – Ceppo Varese  Sapien Stone – Crema Neve

Sapien Stone – Crema Neve  Sapien Stone – Dark Marquina

Sapien Stone – Dark Marquina  Sapien Stone – Fior Di Bosco

Sapien Stone – Fior Di Bosco  Sapien Stone – Grand Antique 4D

Sapien Stone – Grand Antique 4D  Sapien Stone – Grey Earth

Sapien Stone – Grey Earth  Sapien Stone – Grigio Savelli – Cashmere

Sapien Stone – Grigio Savelli – Cashmere  Sapien Stone – Kuroca 4D

Sapien Stone – Kuroca 4D  Sapien Stone – Light Earth

Sapien Stone – Light Earth  Sapien Stone – Malm Black

Sapien Stone – Malm Black  Sapien Stone – Malm Grey

Sapien Stone – Malm Grey  Sapien Stone – Noir

Sapien Stone – Noir  Sapien Stone – Palladium Grey

Sapien Stone – Palladium Grey  Sapien Stone – Piasentina

Sapien Stone – Piasentina  Sapien Stone – Pietra Grey

Sapien Stone – Pietra Grey  Sapien Stone – Platinum White

Sapien Stone – Platinum White  Sapien Stone – Premium White

Sapien Stone – Premium White  Sapien Stone – Rovere Baio

Sapien Stone – Rovere Baio  Sapien Stone – Rovere Buckskin

Sapien Stone – Rovere Buckskin  Sapien Stone – Sand Earth

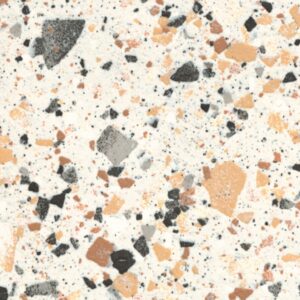

Sapien Stone – Sand Earth  Sapien Stone – Seminato Beige

Sapien Stone – Seminato Beige  Sapien Stone – Seminato Candido

Sapien Stone – Seminato Candido  Sapien Stone – Seminato Nero

Sapien Stone – Seminato Nero  Sapien Stone – Silver Wave 4D

Sapien Stone – Silver Wave 4D  Sapien Stone – Taj Mahal

Sapien Stone – Taj Mahal  Sapien Stone – Uni Ice

Sapien Stone – Uni Ice  Sapien Stone – Urban Antracite

Sapien Stone – Urban Antracite  Sapien Stone – Urban Argento

Sapien Stone – Urban Argento  Sapphire Brown

Sapphire Brown  Sea Bed

Sea Bed Semi Precious Panel – Amazonite

Semi Precious Panel – Amazonite  Semi Precious Panel – Amethyst

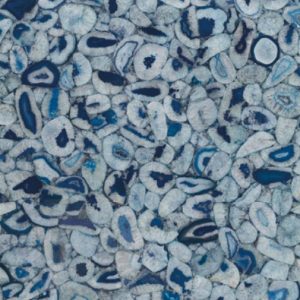

Semi Precious Panel – Amethyst  Semi Precious Panel – Blue Agate

Semi Precious Panel – Blue Agate  Semi Precious Panel – Grey Agate

Semi Precious Panel – Grey Agate  Semi Precious Panel – Iron Pyrite

Semi Precious Panel – Iron Pyrite  Semi Precious Panel – Jaguar

Semi Precious Panel – Jaguar  Semi Precious Panel – Lapis Lazuli

Semi Precious Panel – Lapis Lazuli  Semi Precious Panel – Malachite

Semi Precious Panel – Malachite  Semi Precious Panel – Mother of Pearl

Semi Precious Panel – Mother of Pearl  Semi Precious Panel – Picasso Gem

Semi Precious Panel – Picasso Gem  Semi Precious Panel – Rose Quartz

Semi Precious Panel – Rose Quartz  Semi Precious Panel – Tigers Eye

Semi Precious Panel – Tigers Eye  Sequoia

Sequoia  Shiwakashi

Shiwakashi  Silver Black Onyx

Silver Black Onyx  Silver Cloud

Silver Cloud  Silver Wave

Silver Wave  Silver Wind

Silver Wind  Sivec

Sivec  Sky Blue

Sky Blue  Sodalite Blue Marble

Sodalite Blue Marble St. Hubert

St. Hubert  Stargate

Stargate  Statuary

Statuary  Steel Grey

Steel Grey  Stonethica – Bardiglio

Stonethica – Bardiglio  Stonethica – Carrara Mix

Stonethica – Carrara Mix  Stonethica – Pietra Cardoso

Stonethica – Pietra Cardoso  Strata Brown

Strata Brown  Stratus Boquira

Stratus Boquira  Striato Olympo

Striato Olympo  Super White

Super White  Taj Mahal

Taj Mahal  Tan Brown

Tan Brown  Terra Bianca

Terra Bianca  Thassos

Thassos Thunder White

Thunder White  Titanium Blue

Titanium Blue  Topaz White

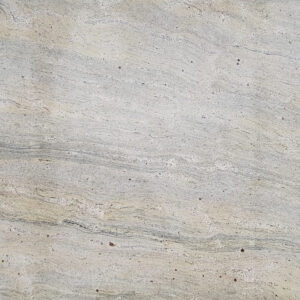

Topaz White  Travertine Classic

Travertine Classic  Travertine Cross-Cut

Travertine Cross-Cut  Travertine Light

Travertine Light  Travertine Red

Travertine Red  Travertine Silver

Travertine Silver  Tropical Black

Tropical Black  Tropical Green Quartzite

Tropical Green Quartzite  Tundra

Tundra  Tuscan White

Tuscan White  Typhoon Green

Typhoon Green  Ubatuba

Ubatuba  Utopia

Utopia Valley White

Valley White  Verde Alpi

Verde Alpi  Verde Antiqua

Verde Antiqua  Verde Bamboo

Verde Bamboo  Verde Cosmopolitan

Verde Cosmopolitan Verde Cristina

Verde Cristina Verde Fantastico

Verde Fantastico  Verde Italia

Verde Italia  Verde Lapponia

Verde Lapponia  Verde Levanto

Verde Levanto  Verde Luana

Verde Luana  Verde Marina

Verde Marina  Verde Olomont

Verde Olomont  Verde Savannah

Verde Savannah  Verde St. Denis

Verde St. Denis  Verde Tabriz

Verde Tabriz  Verde Tinos

Verde Tinos  Verde Vitoria

Verde Vitoria Via Lattea

Via Lattea  Visag Blue

Visag Blue  Viscount White

Viscount White  Vivaldi

Vivaldi  Volakas

Volakas  Volcano Quartzite

Volcano Quartzite  Volga Blue

Volga Blue  Vratza

Vratza  White Beauty

White Beauty  White Ice

White Ice  White Onyx

White Onyx  Whitewood

Whitewood  Wild West

Wild West  Zimbabwe

Zimbabwe